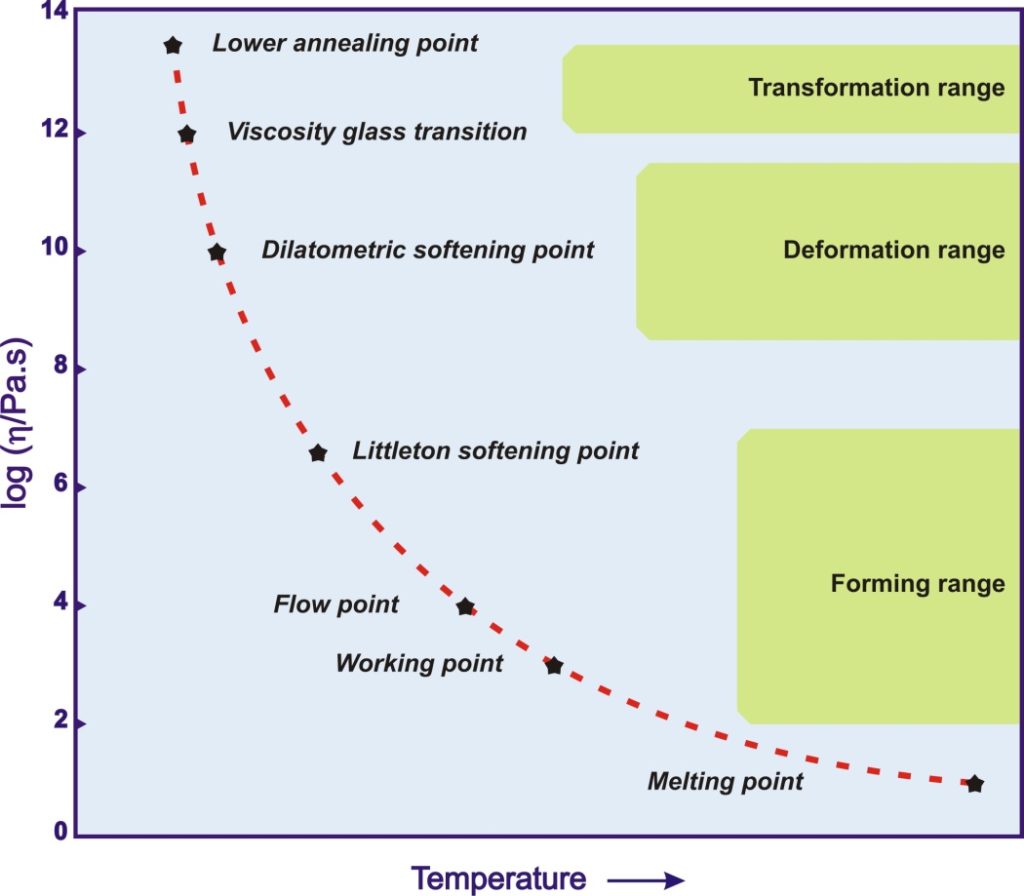

Viscosity is an important physical parameter which determines the flow of material. The knowledge of viscous behavior is one of the key factors for fabrication of glasses. The typical viscosity curve is plotted in Fig. 1. Important points and ranges are apparent in this figure.

In the case of glasses and their undercooled melts, viscosity influences also the processes of structural relaxation and crystallization. Structural relaxation is in fact a very slow rearrangement of thermodynamically unstable glass toward equilibrium. This process can be realized through viscous flow and therefore is influenced by it. Crystallization process which may occur in undercooled melts is also influenced by the diffusion coefficient in the glassy matrix and therefore by its viscosity.

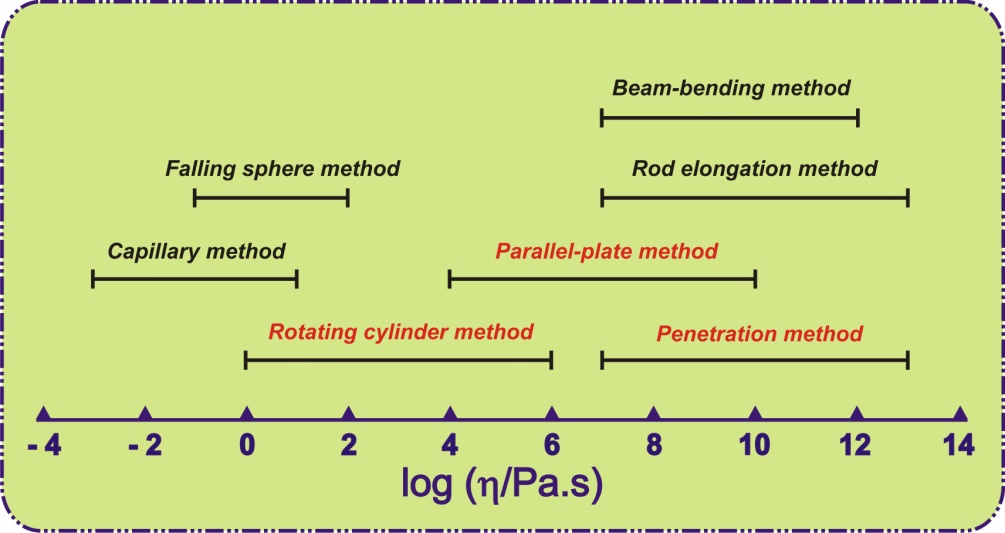

The most of amorphous chalcogenides are considered to be Newtonian fluids. Their viscosity coefficients are dependent only on pressure and temperature. Nevertheless, the pressure dependence is often neglected in the case of condensed phase. Measurements of the pressure dependencies are for inorganic glass-formers complicated because the combination of a high-pressure and high-temperature apparatus is needed. This difficulty, together with small influence of pressure on viscosity at common pressures, caused that most works dealing with the viscosity of inorganic glass-formers study only the temperature dependence of viscosity. Most important measuring methods for determination of dynamic viscosity of chalcogenide glass-formers are summarized in Fig. 2 including the typical range for measurement.

It is apparent that no method covers whole viscosity interval from melt to glass. The most widespread methods for determination of higher viscosity of chalcogenide glass-formers are penetration method followed by parallel-plate one. The dominance of penetration method is caused by the frequent use of it, mainly by Russian authors. Other two methods for high viscosity region, rod elongation method and beam-bending method are used only occasionally. Capillary and rotating cylinder methods are the most popular for determination of dynamic viscosity in the region of lower viscosity. Falling sphere method is used only rarely. Other very popular method for melts is torsion oscillating cup method which is used for determination of kinematic viscosity.

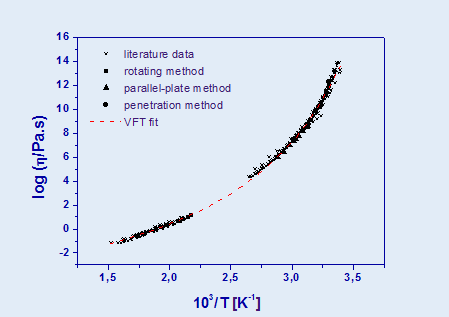

Fig. 3 shows viscosity data determined in our laboratory together with literature data for one of the base and also many times measured chalcogenide material, amorphous selenium. The plot is in typical form as dependence of viscosity logarithm on reciprocal temperature.

Data on figure are divided into two regions. First one is the region of low viscosity which is above melting temperature. The second one is region of high viscosity which is divided into two other regions, regions of glass and undercooled melt. These regions are divided by temperature T12. T12 is temperature where the viscosity value is 1012 Pa.s. This temperature is denoted as viscosity glass transition temperature and was fixed by definition. The measuring of viscosity in upper region of viscosity curve is limited form both sides. Upper region of glass can be hardly measured due to the long times which is necessary to reach equilibrium value. It is caused by long relaxation times. The lower region of undercooled melt is immeasurable due to the cold crystallization of sample. Growing crystals in this region strongly influences the flow of material and viscosity values cannot be determined here. Appropriate fit of measured data is also very important. Two empirical equations are usually used in the case of amorphous materials. They are two-parameters Arrhenius type equation and three-parameters Vogel-Fulcher-Tammann equation (VFT).